Using flange spray shields – Getting the most out of qualitative spray shields

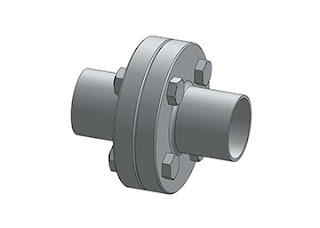

Flange guards are the protective

shields which are utilized to keep the leakage of the different harmful

chemicals from the joints of the pipelines, valve, flanges, and so on. The

flange spray shields are installed in the pipeline joints to prevent leakage of

dangerous substances.

The chemical enterprises work at

the risk of endangering the lives of the workers that work there as well as our

environment each and every day. Different chemical ventures and pharmaceuticals

work with the distinctive sorts of the corrosive, chlorine, soluble, caustics

and other harmful chemicals which are profoundly reactive with natural

substances.

There are many purposes for

getting flange spray shields at the

pipeline joint. Some of the best known reasons are:

Prevent spray-outs at any cost: The device is sufficient valuable

to obstruct the way of any spray out from the joints of the pipelines and

valves. It is a compelling method to keep the circumstances that creates

damage.

Anticipate corrosion at the joints: The cruel chemicals have

erosion framing properties since a few chemicals are profoundly reactive with

the metals. Flange guards are the shoddy answer for protect the pipelines against

rust and consumption while going about as a protective layer between the

chemicals and the outer surface.

As the indicator of any leakage: The protective shield installed at

the flange joints go about as a leakage indicator on the grounds that the vast

majority of the products accompany either PH fix indicator which changes

shading when it comes in the contact of any corrosive or base or the device

comes in straightforward made material which unmistakably demonstrates any

leakage.

Avoid mist formation: The pipelines conveying the chemicals are

extreme yet joints are similarly touchy with regards to leakage. Installing

protective shields at the place is the convenient answer for evade any mist

formation. It additionally stays away from the tainting to the man, machine,

and condition.

Conclusion

The device is generally installed in the

chemical businesses and pharmaceuticals to maintain a strategic distance from

the circumstances of leakage, spray-outs, and mist formation. In any case, the

extent of installing the device is a lot more extensive. They are installed at

the spots situated close to thickly populated regions including oil and natural

gas lines installed close to the hot surfaces or the corrosive lines close to

the staff or walkways which are exceptionally populated. The spray shields

along with stud bolt b7 are also

used in the businesses which are working with the dangerous chemicals at the

statures likewise require the installation of the device.

Follow us: https://myspace.com/indanasteels

Comments

Post a Comment