Know about the Safety Spray Shields

To reduce and prevent injury to workers and harmful damage of property, and equipment by temporarily containing hazardous sprays and leaks Safety Spray Shields are designed. Early leak detection by preventing downtime from recordable or failures accidents helps reduce maintenance costs in plants.

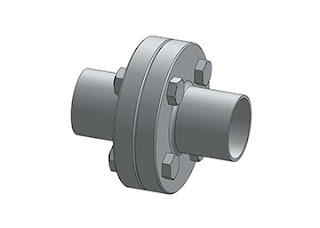

Flange Wraps, Flange spray shields, and Flange Protectors are most commonly used on flanges in caustic chemical services and acid. They are available for any other type of pipe joint, unions, or valves.

Used in a variety of industries, Safety Shields also known as flange guards. Prevention of mist formation and harmful spray-outs from failing pipe joints, of dangerous, corrosive and toxic liquids such as steam, oil or acid is their primary application.

For a large number of high profile industrial incidents around the world Pipe, joint failures have been responsible. Steam, oil, and Acid jet spray-outs either directly or through consequent explosions and fires have resulted in many severe personal injuries.

To prevent the formation of explosive mist or jet leaks Industry regulators have recognized the importance of shielding pipe joints (flanges, couplings, valves, hoses). Such spray-outs in many cases can have catastrophic effects, causing loss of life and considerable plant downtime, and even resulting in explosions or fire capital expenditure.

The last line of defense is offered by Spray or Safety Shields. To contain the leak indefinitely they are not designed; allowing liquid release vertically they are designed to control the leak safely. They ultimately prevent harmful spray out. The Stud bolt b7 is very useful.

Safety Shields

For applications where the sight of the flange/joint must not be obscured this shield is generally used. Providing visual indication liquid releases within the shield can be seen. It should be noted, however, where external condensation/liquid may result in a false indication of leakage that we do not recommend this shield for applications.

Due to the Teflon/Kevlar and technical fabric thread used for stitching the shield is suitable for a range of corrosive chemicals. Please consider the standard ST/ST shield or PTFE for higher temperatures and strong pressures and acids. For caustics, acids, fuel, solvents, seal oil, and lubrication applications this shield is typically used.

The last line of defense is offered by Spray or Safety Shields. To contain the leak indefinitely they are not designed; allowing liquid release vertically they are designed to control the leak safely. They ultimately prevent harmful spray out. The Stud bolt b7 is very useful.

Safety Shields

For applications where the sight of the flange/joint must not be obscured this shield is generally used. Providing visual indication liquid releases within the shield can be seen. It should be noted, however, where external condensation/liquid may result in a false indication of leakage that we do not recommend this shield for applications.

Due to the Teflon/Kevlar and technical fabric thread used for stitching the shield is suitable for a range of corrosive chemicals. Please consider the standard ST/ST shield or PTFE for higher temperatures and strong pressures and acids. For caustics, acids, fuel, solvents, seal oil, and lubrication applications this shield is typically used.

Comments

Post a Comment