Stud Welding: Details about the Stud Welding Process

Stud Welding

There are actually many different applications involved with welding even though it is believed by many people that there is only one basic welding application.

Stud welding process is one of these areas, where onto another metal piece a formed nut or bolt is welded. To automatically feed the bolts into the spot welder this process may include using stud welding equipment.

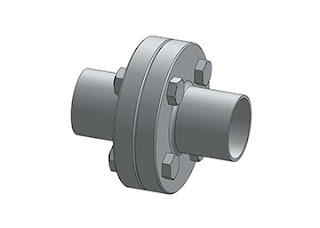

By using the stud as an electrode arc stud welding, or Stud welding, involves joining the Stud bolt b7 to a flat plate. On the type of metal that is used, the polarity that is chosen for the particular stud welding application will be based on. For example, while steel demands direct-current electrode negative aluminum usually requires DCEP.

Usually have a flange in order to form the weld, with some type of small nubs that melt during the process the weld nuts used in stud (or arc) welding. To form the desired weld the un-threaded, necked down part of the weld nuts also help.

The use of a flux, called a ferrule is another aspect of this type of welding application. Retaining the melted metal in the desired weld zone and preventing oxidation a ferrule is a ceramic ring that concentrates the generated heat.

|

| Stud bolt b7 |

Weld Studs

As a part of this efficient application Stud welding systems use weld studs. These studs can range from 1/4" to 5" or more in length, are between 14 gauges to 3/8" diameter, and from capacitors are discharged. Two purposes are there as the tips on the weld end of the stud:

Disintegration: Solidifying the weld onto the base material, Weld end tips disintegrate once the trigger is pulled on the melting and welding gun. The Flange sprays shields also very useful.

Timing: Keeping the studs off of the base material that is being welded the tips act as a timing device that.

Arc Studs

Helping to promote the welding process with an aluminum flux ball Arc studs are usually loaded on the weld end. They can range from 8 up to a 1 1/4" diameter stud, and these unique studs are an integral part of stud welding equipment.

Comments

Post a Comment